Spray painting services offered by Thakur Electronics as an Electronic Contract Manufacturing (ECM) company in India, involve the application of protective coatings or finishes on electronic components, enclosures, or products. These services are essential for enhancing the appearance, durability, and functionality of electronic devices while also providing protection against environmental factors. Here's an overview of the spray painting services typically provided by Thakur Electronics.

We work with clients to select the appropriate paint or coating materials based on factors like the type of substrate (e.g., plastic, metal), desired finish (e.g., glossy, matte), and environmental requirements (e.g., resistance to moisture, chemicals, UV radiation).

Proper surface preparation is crucial for achieving a quality finish. We perform cleaning, degreasing, sanding, or other surface treatments to ensure paint adhesion and a smooth surface.

Certain areas of the electronic components or products may need to be masked or taped off to prevent the paint from covering or affecting specific regions, such as connectors or sensitive components.

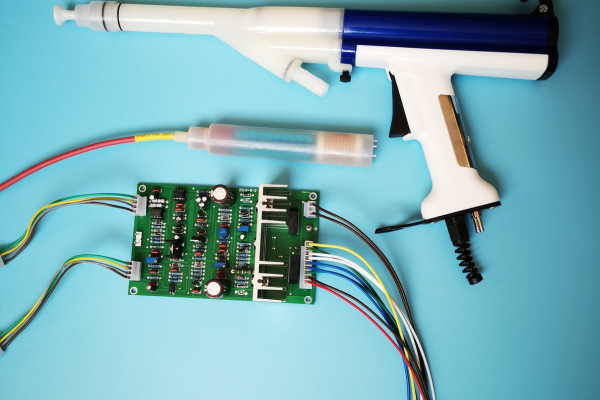

As an ECMS Company we employ professional spray painting techniques, including airless spray, air-assisted airless, and conventional spray methods, depending on the specific requirements and materials.

We provide custom color matching services to ensure that the painted components or products match the desired color scheme or branding.

Rigorous quality control processes are in place to inspect and verify the quality and consistency of the painted finish. This includes inspections for uniformity, adhesion, and any defects.

After the application of paint or coatings, we use controlled environments and curing methods (such as baking or air drying) to ensure that the finish is properly cured and ready for further processing or assembly.

We offer a variety of surface finishes, including gloss, semi-gloss, matte, textured, or custom finishes to meet the aesthetic and functional requirements of the product.

We ensure compliance with environmental regulations and safety standards when handling paint materials and waste disposal.

Spray painting services at Thakur Electronics can be scaled to accommodate both low-volume and high-volume production requirements.

We maintain comprehensive quality assurance procedures, including documentation, traceability, and testing, to ensure that painted components or products meet the required specifications.

Spray painting services provided by Thakur Electronics as a Leading ECM service provider company in India are crucial for achieving a professional and functional appearance for electronic products. Whether it's coating electronic enclosures, front panels, or other components, these services help protect against corrosion, wear, and environmental factors while enhancing the visual appeal of the finished products.