Injection molding services offered by Thakur Electronics as an Electronic Contract Manufacturing (ECM) company in India, involve the manufacturing of plastic components or parts through the injection molding process. This process is widely used in the electronics industry to produce various plastic components for electronic devices and products. Here's an overview of the injection molding services provided by ECM Thakur Electronics.

We companies work with clients to select the appropriate thermoplastic or thermosetting plastic materials based on factors like mechanical properties, chemical resistance, electrical properties, and compliance with industry standards.

The first step in injection molding is the design and fabrication of molds or tooling. As a leading ECM company we have the capability to design and produce molds in-house or work with trusted tooling partners.

We also collaborate with clients to optimize the design of plastic components for the injection molding process, ensuring that the design is suitable for efficient and cost-effective manufacturing.

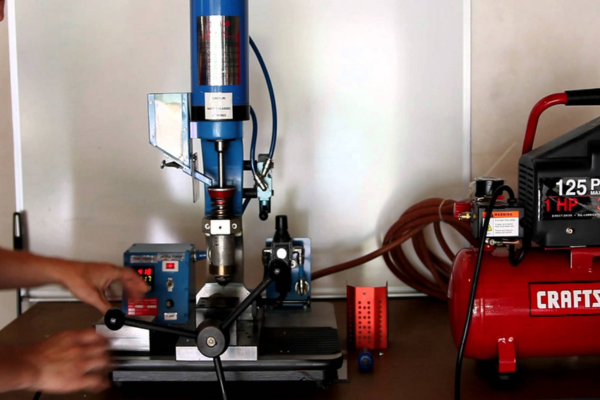

The injection molding process involves melting plastic resin pellets and injecting the molten material into the mold cavities under pressure. We use state-of- the-art injection molding machines to achieve high precision and consistency in the manufacturing process.

Rigorous quality control measures are in place to inspect and verify the quality of molded parts. This includes dimensional inspections, visual inspections, and checks for defects or imperfections.

Injection molding services can be scaled to accommodate both low-volume and high-volume production requirements. We have the capacity to produce thousands to millions of parts, depending on the project.

We are very mindful of environmental sustainability and may offer options for recycling or environmentally friendly materials.

Injection molding services provided by Thakur Electronics as an ECM company in India ,are essential for producing a wide range of plastic components used in electronic devices, including enclosures, connectors, bezels, and housings. These services are valuable for achieving precise and consistent results, reducing production costs, and meeting quality and regulatory requirements in the electronics industry.